High-efficiency and large-capacity VRF system.

Large-capacity VRF systems using R410A with advanced technology. Newly designed next generation VRF!

2-Pipe ECOi 6N Series. Energy savings

The operation efficiency has been improved using highly efficient R410A refrigerant, new DC inverter compressor, new DC motor and new design of heat exchanger.

1. Standard Cop setting model / 2. High Cop setting model

Cooling / Heating

2-Pipe ECOi 6N Series. Extended operating range

Heating operation range: Extended heating operation range enables heating even when outdoor temperature as low as -25°C. Using a wired remote control, indoor heating temperature range can be set from 16°C to 30°C.

1. Cooling operation range: -10°C DB to +43°C DB. Outside air temperature (°C DB)

2. Wide temperature setting range. Outside air temperature (Upto 15 (°C WB)

Connectable indoor/outdoor unit capacity ratio up to 200%

VRF systems attain maximum indoor unit connection capacity of up to 200 % of the unit’s connection range, depending on the outdoor and indoor models selected. So for a reasonable investment, VRF systems provide an ideal air conditioning solution for locations where full cooling/heating are not always required.

A. System (HP) / B. Connectable indoor units: 130% / C. Connectable indoor units: 200%.

If more than 100% indoor units are operated with a high load, the units may not perform at the rated capacity. For the details, please consult with an authorized Panasonic dealer.

Newly designed fan. Optimized air flow and noise reduction

Newly designed fan and bell-mouth reduces stress to fan by dispersing fast wind speed. Thus, lower air resistance results in lower energy consumption.

The turbulent flow (blue part) can be suppressed and the noise can be reduced. Even though the high speed circulation is utilized, the noise level is held at the same level as normal.

Increased piping lengths and design flexibility

Adaptable to various building types and sizes. Actual piping length: 180 m. Maximum piping length: 1000 m. Maximum total length: 1000 m

1. System difference of elevation

2. Difference in elevation between indoor units

3. Actual length

* 40 m if the outdoor unit is below the indoor unit.

Easy to design solutions for schools, hotels, hospitals and other large buildings

Difference between maximum and minimum pipe runs after first branch can be a maximum of 50 m; larger pipe runs can be up to 180 m.

L1 = Longest pipe run

L2 = Shortest pipe run

L1 - L2 = Maximum 50 m

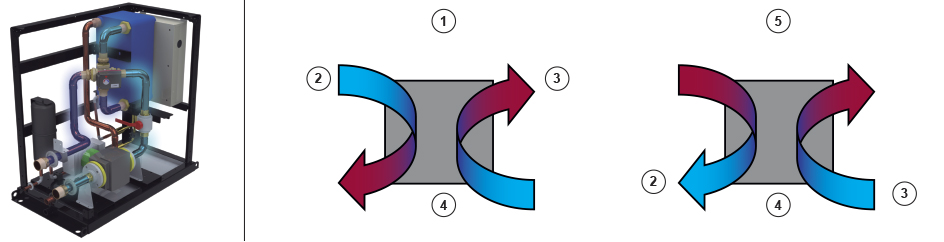

Extended compressor life by uniform compressor operation times

Total compressors run-time is monitored by a built-in microcomputer, which ensures that operation times of all compressors within the same refrigerant circuit are balanced. Compressors with histories showing shorter run times are selected first, ensuring equal wear and tear across all units and extended working life for the system. Maximum total length: 1000 m

1. A, C: DC inverter compressor

2. B, D: Constant speed compressor

3. Load increase

4. Example: Time leveling of compressor operating hours

5. Compressor In case of the above graph, compressor drives from 4 / 2 / 3 / 1 / 5

Non-stop operation during maintenance

In the event of an indoor unit malfunctioning, other indoor units can be set to continue operation even during maintenance.

1. Lights,etc.

2. Breaker

3. In operation

4. Power cut off (Under renovation)

Automatic backup operation in the case of compressor and outdoor units malfunction

Backup operation is applied during in the case of emergencies. If error message is displayed, please contact your local service office. (Except for 8 HP single unit installation).

1. Even if either Fan motor or Sensors are failed

2. Even if a compressor is failed

3. Even if a compressor at single system is failed

4. New function

5. The other outdoor unit can keep running

6. The other compressor can keep running

7. Backup operation can be done

Demand Control Kit

This function limits the maximum operating input at peak time.

The limit value setting for level 1 & 2 can be changed from 40% ~ 100% by 5% when the system is commissioned.

Power input level (vs. rated condition):

Level 1: 100% (at ship) / From 40%-100% setting can be changed (by 5% step)

Level 2: 70% (at ship) / From 40%-100% setting can be changed (by 5% step)

Level 3: 0% (Forcible thermo-OFF)

Operating image: 1. Power input / 2. Demand level / 3. Level 1 / 4. Level 2 / 5. Limit Max level / 6. Time

CZ-CAPDC2

Demand control input signals sent to this outdoor interface will be transferred to the system via inter-unit control wiring.

Other controls (ex. Operation ON/OFF, Mode switch Cool/Heat) are also available. Demand level 1 & 2 are available.

1. Outdoor unit / 2. Inter-unit wiring terminal / 3. Input terminal / 4. Demand 1 / 5. Demand 2 / 6. Demand controller

ECOi 2-Pipe and 3-Pipe wind protection shield

PAW-WPH1: 1 long side of the outdoor unit (624 x 983 x 489)

PAW-WPH2: 1 long side of the outdoor units (853 x 983 x 489)

PAW-WPH3: 2 long sides of the outdoor units (744 x 983 x 289) (2ER SET)