High Static Pressure Hide Away (PF Type)

The static pressure outside the unit can be increased up to 150 Pa.

Type: 60 kW Standard: 70 Pa / 71 kW Standard: 70 Pa / 100 kW Standard: 100 Pa / 125 kW Standard: 100 Pa / 140 kW Standard: 100 Pa Type: 60 kW Max. available setting: 150 Pa / 71 kW Max. available setting: 150 Pa / 100 kW Max. available setting: 150 Pa / 125 kW Max. available setting: 150 Pa / 140 kW Max. available setting: 150 Pa

More powerful drain pump

Using a high-lift drain pump, drain piping can be elevated up to 785 mm from the base of the unit.

Air inlet

The unit features air inlet on one side, air outlet on the other side. The air inlet filter can be pulled out from the side of the unit and can be folded. Easy access if through the maintenance opening.

When air inlet duct (field supplied) is connected on suction side, remove the filter, frame and insulation materials on both sides of the unit. Connect the duct on the suction side of the unit by using prepared holes on the unit.

Air outlet site

A rectangular duct flange for the air outlet is fitted as standard. Round outlet flange kits are available as an optional accessory kit.

Circle duct flange (option)

CZ-56DAF2 (2 SA outlet): 2 exits x Ø 200 mm

CZ-90DAF2 (3 SA outlet): 3 exits x Ø 200 mm

CZ-160DAF2 (4 SA outlet): 4 exits x Ø 200 mm

A: Standardized height of 290 mm for all models Height standardization enables easy and uniform installation for models with different capacities.

B: Built-in Drain pump (DC motor pump)

C: External electrical equipment box makes maintenance easy P-link PCB

D: - Built-in filter - Side removable filter

E: Standard. Round flange : CZ-160DAF2 ϕ200 outlet frange x 4 ports

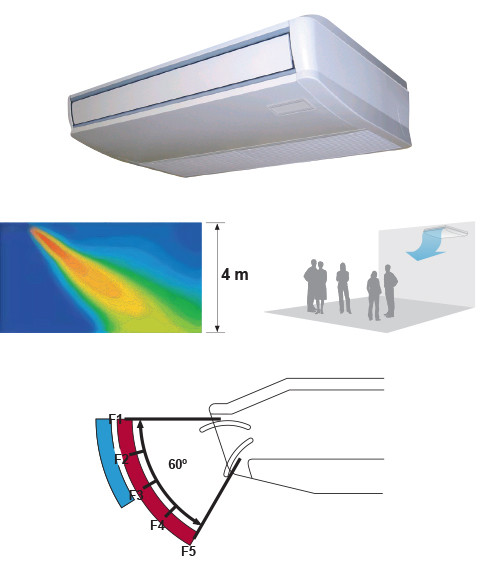

1. Detection area 6m / 2. Approx 1m / 3. 1,8m Dead Zone / 4. Human detection area (2,5m height angle 30°)